From materials to manufacturing, products to recycling — sustainability is about considering every step of our process. Smart design is a start, but our products should also serve a greater purpose once they leave our factory. That’s why every single shoe and ribbon we’re making is remarkably durable. Read on to find out how we pursue sustainability in the following 4 areas.

We don’t believe in fast fashion, so our products are built to last.

Our footprint is light, but we’re working hard to do better.

The jute we use for our Chilón model is all natural and biodegradable. More precisely, it’s a natural fiber that’s braided into a rope. These ropes are then processed to make a sandal.

Our rubber is obtained from elastomers, synthetic thermoplastics, polymers and minerals. Therefore, it’s free and clear of all constituents or derivatives of animal origin. We’re proud to say that our rubber is 100% vegan, animal and eco-friendly.

All leather is tanned in strict compliance with the REACH regulation. This authority regulates banned substances in the EEC, subject to environmental regulations. Also worth mentioning is that our supplier is a member of the Leather Working Group with silver category.

Our factory in Spain uses water-based glue for the different gluing processes, which is considered as ‘greenguard’. Also, the effectiveness, quality and result in use is perfectly comparable to conventional glues.

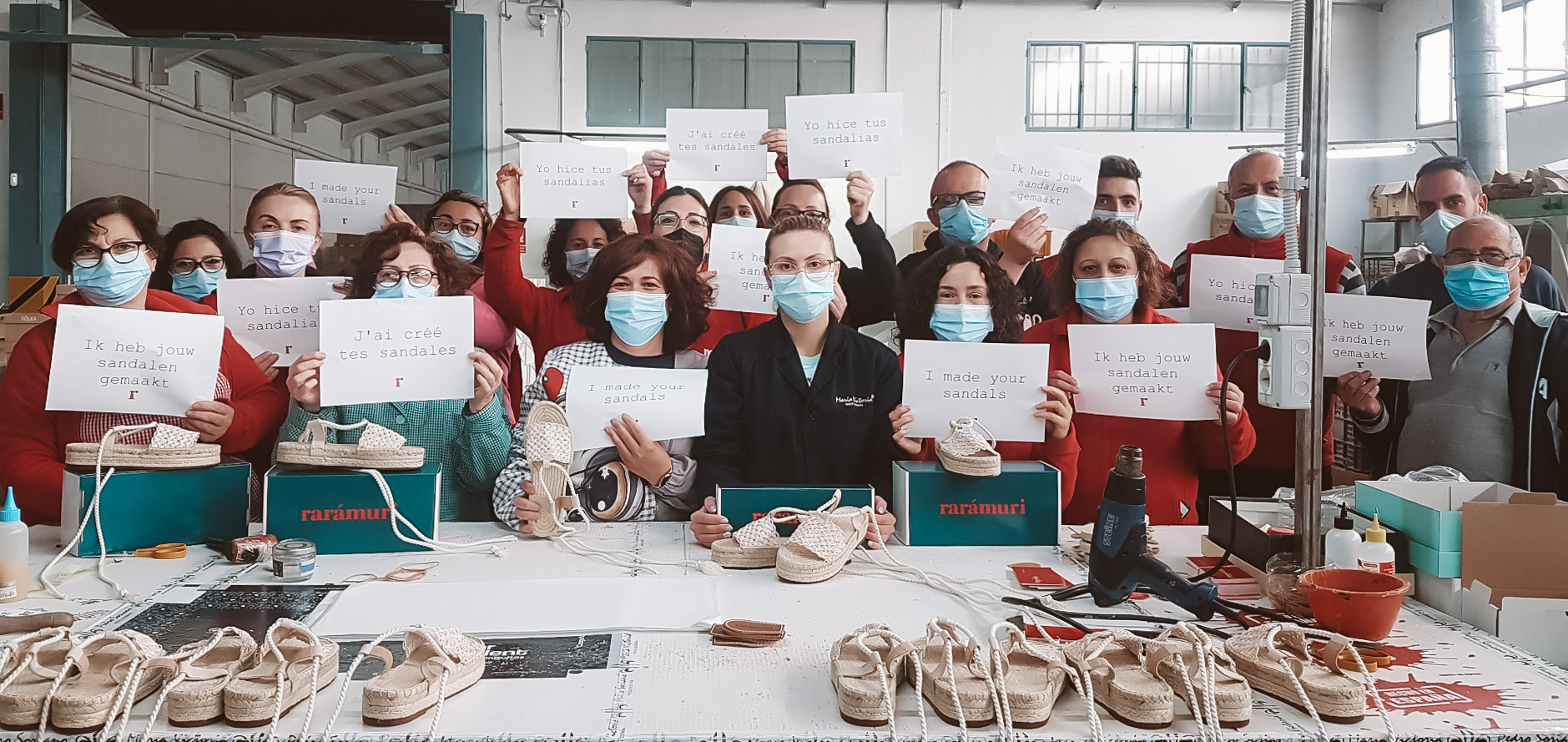

With certainty and honesty, we can say that our factory in Spain scores well in terms of sustainability. Our shoes are made in a safe working environment that strives for maximum reduction of water, energy and waste consumption.

Water consumption in the factory is very low, since it’s only used for basic vital services. The production of our shoes doesn’t require any use of water at all.

Not only does our factory have the latest machinery, the electricity consumption is managed and limited to what is strictly necessary. Therefore, the use of CO2-producing machinery is very low.

Our factory has a contract with a waste management company (CESPA – Gestores de Residuos). As its name indicates, this company is in charge of managing waste in order to reduce its environmental impact.

Yes, our energy is green. The company Nace-Energía Eléctrica with which our factory has a contract supplies green energy.

Our shoe boxes are made of 100% recycled material & the inks used are all of vegetable origin.

Our factory is pending FSC membership, which is an official organization that certifies that the trees used are replaced by new trees that are planted in their place, and that the wood does not come from discriminatory or clandestine logging.

Now that you know all about our shoes and packaging, it’s time for the ribbons. Our beautiful ribbons are handmade and produced locally at a sheltered workshop, called KUNNIG.

At the workshop, a large team of great employees, who are distanced from the employment market, are given a chance to be part of the working society. We truly feel blessed to work with them. Not only because we value their professionalism, but even more their enthusiasm and big smiles.

Subscribe to our newsletter and get 10% discount on your order!